Pneumatic AC or Inverter Seam Welder, Stable and Durable

Overview Product Description Classification As per power source: AC and inverter DCAs per welding wheel direction: Horiz

Overview

Q: What about your standard delivery date ? A: Usually 30-60 working days. Our company provide just-in-time delivery2

Q: How can you guarantee quality? A: You could test samples before order,and we have professional QC and precise machining equipment; Always final Inspection before shipment;3

Q: How long is the guarantee? A: For one year after the custumer received the machine.4

Q: What do we need to do if the machine fails? A: In the guarantee time (1 year),we will send the spare parts to you for free,and provide the technical consultant for any time.5

Q: Can I make my own design and logo on the product? A: Yes, we do OEM.Welcome global partners.6

Q: what is the packing mode? A: wooden case or FCL with container.7

Q: what is your after-sell service? A: After-Sales 1) Training your workers how to install the machine, how to use the machine. 2) Engineers available to service machinery overseas 3) 1-year guarantee ( free maintain in a year) 4) Replacement parts and other accessories provided

Basic Info.

| Welding Speed | 0.7-3.9 M/Min |

| Primary Voltage | 380/1 V/Phase |

| Frequency | 50Hz |

| Phase | 3 |

| Transport Package | at Customer′s Requrest |

| Specification | export standard |

| Trademark | xinchang |

| Origin | Ningbo China |

| HS Code | 85152900 |

| Production Capacity | 500sets/Year |

Product Description

Product Description

Classification

As per power source: AC and inverter DCAs per welding wheel direction: Horizontal and longitudinalAs per qualiy grade: Top quality and simple typeFeatures1. Adopt 3-phase motor which is variable frequency, average welding speed, easy to adjust, and stability.2. Welding circuit loop is by means of internal water cooling, welding wheel (electrode) are by means of external water cooling.3. The parts of electric conduction turning on welding machine are designed to be embedded silver bushings structure, the base of electric conduction is lubricated by hermetic oil and be cooled down by water so as to silver bushings turn flexibly not to lock.4. Both horizontal and longitudinal two type seam welders. H: Horizontal, L: Longitudinal.Main advantage different than other ones1. The parts of electric conduction turning on welding machine are designed to be embedded silver bushings structure, the base of electric conduction is lubricated by hermetic oil and be cooled down by water so as to silver bushings turn flexibly not to lock.2. The rotation axis within base of electric conduction adopt nanometer ceramic spraying different other factor's nylon, it is more anti-friction, thereby, machine life is longer.3. Cylinder guidance bar is square different other's round, then, the welding wheel is not easy to skewed. Therefore, welding quality are better than round guidance bar ones.Machine constitute1. Machine body: Use vertical reinforcing structure, use good quality thickness steel plate to weld2. Transformer: Use silicon sheets of 15000 gauss permeability to pile up. There is cooling water in inside, using full copper alloy core, reducing impedance, improving the utilization of power, 50% duty cycle to ensure the requirement of long time welding, big output power. The useful lifetime is longer, noise is smaller, structure is more compact and reasonable.3. Solenoid: From Taiwan, High speed and quality4. Cylinder: Adopt high accurate, anti-friction hard material, which is duralumin, without rust, lower friction, lower noise and adding pressure is faster, thereby reducing the weld spatter.5. Welding wheels: With CuCrZr materials, very anti-friction. By means of water cooling, longer service life.6. Switches7. Air source processor8. Electric conduction base-- silver bushings structure9. Controller: Chinese Top brand, from sunke10. Motor: Mitsubishi Japan11. Cooling water system12. Compressed air system13. Monitor & alarm systemApplicationsBe widely used in metal, electrical appliances, fuel or water tank etc. Most be suitable for basin, barrel, tank or sealed and thin containers weld of low carbon steel or stainless steel materials.Product Parameters

| Model | FN-80-H(L) | FN-100-H(L) | FN-160-H(L) | |

| Rated capacity | KVA | 80 | 100 | 160 |

| Primary voltage | V/PHASE | 380/1 | 380/1 | 380/1 |

| Frequency | HZ | 50 | 50 | 50 |

| Max. short circuit current | KA | 26 | 30 | 40 |

| Electrode stoke | mm | 100 | 100 | 100 |

| Welding speed | m/min | 0.7-3.9 | 0.7-3.9 | 0.7-3.9 |

| Electrode pressure | N | 6000 | 6000 | 7800 |

| Welding capacity(low carbon steel) | mm | 1.2+1.2 | 1.5+1.5 | 2.0+2.0 |

| Voltage of motor | V/PHASE | 380/3 | 380/3 | 380/3 |

| Power of motor | W | 550 | 750 | 750 |

| Cooling water flux | L/min | 8 | 8 | 10 |

| weight | Kg | 380 | 510 | 630 |

Detailed Photos

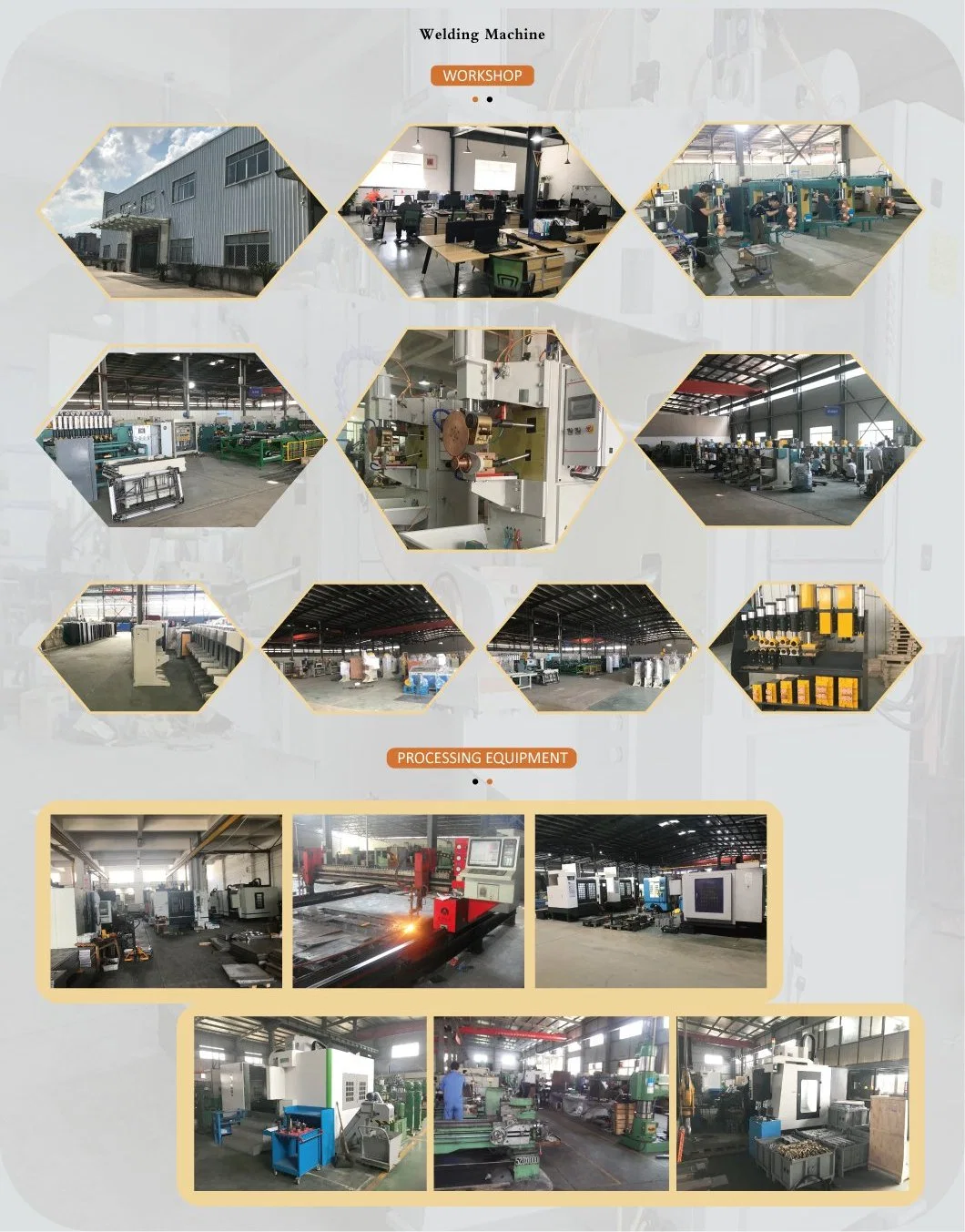

Company Profile

FAQ

1Q: What about your standard delivery date ? A: Usually 30-60 working days. Our company provide just-in-time delivery2

Q: How can you guarantee quality? A: You could test samples before order,and we have professional QC and precise machining equipment; Always final Inspection before shipment;3

Q: How long is the guarantee? A: For one year after the custumer received the machine.4

Q: What do we need to do if the machine fails? A: In the guarantee time (1 year),we will send the spare parts to you for free,and provide the technical consultant for any time.5

Q: Can I make my own design and logo on the product? A: Yes, we do OEM.Welcome global partners.6

Q: what is the packing mode? A: wooden case or FCL with container.7

Q: what is your after-sell service? A: After-Sales 1) Training your workers how to install the machine, how to use the machine. 2) Engineers available to service machinery overseas 3) 1-year guarantee ( free maintain in a year) 4) Replacement parts and other accessories provided

previous:

Manufacturer Price Hand

Send to us