165kVA Inverter Welding Machine for Compressor

165KVA Inverter Welding Machine for Compressor Technical parameter Cotroller introduction: 1) Output frequency of the in

Basic Info.

| Model NO. | DB-165-18018 |

| Max Working Pressure | 9000N/0.5MPa |

| Dimension | 1611*1020*1979mm |

| Max. primary current | 225A |

| Power Supply | 380V+-10% /50Hz/3pH |

| Rated Duty Cycle | 20% |

| Current | Inverter Current |

| Rated Capacity | 165kVA |

| Transport Package | Wooden Case |

| Specification | CE, CCC, ISO9001 |

| Trademark | HERON |

| Origin | Guangzhou, China |

| HS Code | 8515219900 |

| Production Capacity | 50-60PCS/Month |

Product Description

165KVA Inverter Welding Machine for CompressorTechnical parameter

| Item | Parameter |

| Rated capacity | 165KVA |

| Power supply | 380V+-10% /50Hz/ 3phases |

| Rated duty cycle | 20% |

| Max short circuit current | 20500A |

| Max. primary current | 225A |

| Max working pressure | 9000N/0.5MPa |

| External dimension(L*W*H) | 1611*1020*1979mm |

Cotroller introduction:

1) Output frequency of the inverter power is 1000HZ;

2) With automatic correcting system for welding current.

3) Support total Max 64 welding programs, which can be selected form internal or external.

4) It supports proportional valve function: The output voltage is 0-10V. With automatic pressure

calibrating function and pressure can be programmed . With the proportional valve,it can achieve stepper pressure, saddle pressure. It supports two kinds of pressure setting modes, one is percentage mode and the other is KN mode (this function is optional).

5) The welding time for each current pulse is 0 ms to 2000ms;

6) Automatic Repeat Welding Function. When the real time welding current is lower than the lowest-set value,the welder wautomatic execute the repeat welding and the repeat welding times can also be set by user.

7) Counter for Welds. This welder can count the number of welding spots for each part, each shift production, total production, and total welds. It can monitor the missing welds or more welds.

8)Welding parameter can be copied. The welding programs can be input and output by the flash drive. And through thepanel ,the welding programs can be uploaded and downloaded between different machines.

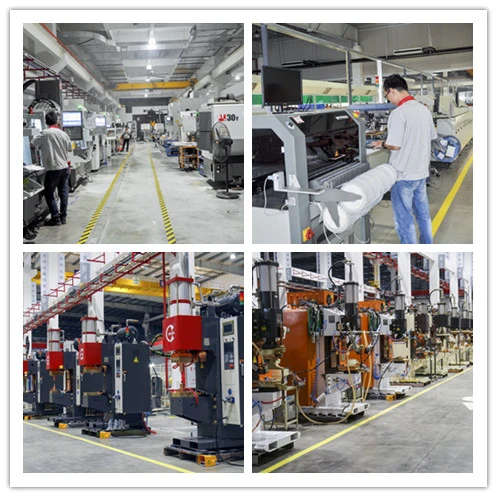

Factory profileFounded in 1997. Heron own over 56,000 square meters property; developed MFDC welding system, Capacitor discharge welding system, three-phase DC welding system; single phase AC welding system; offer a complete range of standard resistance welding equipments; and customize automation resistance welding production system with fixture; pursue high welding technology researching and developing all the time. Our productions apply to different field like: car body production line, automotive part production line, refrigerator compressor welding line, silver tip with copper welding system, hardware welding; home appliance manufacturer line etc ,supplying the high tech and energy saving welding equipment and integrate the working station. Our production lines include: press welders; manual and robotic welding guns, seam welders, bench welders; rocker arm welders ,flash butt welders, multi gun auto welder with wire feeder; customized work station, clinch system with BTM Tog-L-Loc; automatic arc welding stations etc. With ISO9001, CCC, CE certification.

Our long-term cooperative clientsFAQ

1.What's the trade terms?

A: FOB, EX-Work, CRF2.What's the payment term?

A: a. T/T 30% as deposit, 70% should be paid before delivery. b. L/C at sight3. What's the delivery time?

A: 2-3 months after received 30% deposit.4. What's the package way?

A: Wooden case5. Which shipment port?

A: Guangzhou or Huangpu port6.How long is the guarantee?

A: For one year after customer received the machine. (It's not including the comsumables)

Factory Sell CAS 288 :next

Send to us